Prologue to Rapid Prototyping

In examination, improvement and study, models assume a significant part. These created models help to do testing before creation and help to pinpoint the potential issues that are happening because of the plan deficiencies. Prior creating a model was very expensive interaction and furthermore time taking. Be that as it may, with the guide of Computer Numerically Controlled CNC Machining, the speed at which a model is created has expanded. With Rapid Prototyping, this time-frame has even diminished from not many days to a couple of hours.

Fast Prototyping is an added substance fabricating measure that creates a model of an item straightforwardly from a CAD model by building it in layers. For this electronic gear are utilized that forms a three-dimensional model of a projecting from a CAD drawing.

There are various types of Rapid Prototyping accessible relying on the necessities. One can separate between them by the strategies these frameworks utilize to make the layers. Following are not many of the principle sorts of Rapid Prototyping:

Stereo lithography SLA

Stereo lithography utilizes UV beam to harden fluid acrylic polymer layer by layer on a FDM 3d printing stage and after numerous layers, the model in the favored structure is framed. This cycle is carried on in a VAT, a gadget that is topping off with photo curable fluid acryl ate polymer. Stereo lithography is quite possibly the most utilized types of quick prototyping due to exactness Tolerances= 0.0125mm, less time taken relies on the size and intricacy of the part and where parts subtleties are fine and their calculation is too hard to machined.

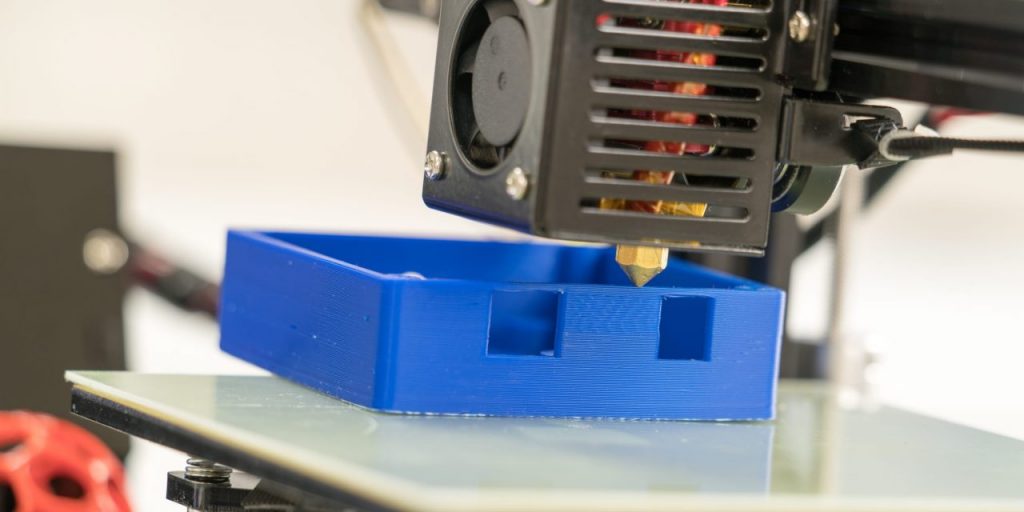

Intertwined Deposition Modeling FDM

Intertwined testimony demonstrating likewise alluded as FDM, is a fast model innovation usually used to change over CAD drawings into actual parts. FDM is a brand name of Stratasys and was created by S. Scott Crump.

FDM chips away at an added substance guideline which expels material in layers. Plastic or wax is softened and condensed in the expulsion head and expelled through a spout. The spout is made to move over a path recognized by the CAD configuration to deliver part. This way single layer is expelled and afterward it is dropped to expel the following layer on top of the first until the whole model is worked, with each layer in turn.

Specific Laser Sintering SLS

Specific Laser Sintering utilizes the rule of sintering. Sintering is a warming interaction that forestalls softening and an intelligible mass is produce. In SLS, metallic or non-metallic powders are sintered utilizing a CAD program guided laser that specifically intertwines the powdered material.

There are not many more sorts of Rapid Prototyping accessible, as; Laminated Object manufacturing, 3D Printing, Solid Base Curing, Optical Fabrication and Photochemical Machining.

Fast prototyping has given creators a few advantages. Architects can look their parts and in the event that any mistake happens they can without much of a stretch fix it. Aside from modern use they have framed piece of production. This advancement interaction gives clear patters to use in projecting. RP has likewise multiplied biomedical science.